WIRELESS

SENSORS

The Most Accurate Innovative

ON-BOARD SCALE SYSTEM

The Strong Way

Quick & Simple Installation

Sensors Mounted In Under 15 Minutes

Accuracy You Can Trust

Under-load Prevention

Stop Leaving Money Behind

Over-load Protection

Know Before You Go

Fleet Management

Put Yourself In The Passenger Seat

Maximize Your Trip Efficiency

Patented Wireless Strain Sensors

SWMS-LC

The only truly wireless scale sensors. Self contained, battery powered unit. No exposed or running wires! Quick & easy install. Mounts directly to vehicle axle. Highly accurate!

Strong Weigh

Brilliant Technology

Made Simple to Use

at an Incredible Value

The market is saturated with on-board scale products and countless, unsupported claims. Promises for accuracy, calibration, durability, and more!

Want a truly simple to install, easy to maintain solution that performs better than the rest? Strong Weigh’s cutting edge technology provides benefits never before seen in on-board scales!

The patented wireless strain sensor can be applied in 15 minutes, allowing a full system to be operational in under an hour! Our proven process eliminates sporadic fluctuations and the need for constant re-calibration.

Strong Weigh consistently provides an accurate and reliable measurement of your truck’s weight every single load you haul. Real-world application with proven accuracy of over 99% makes Strong Weigh the go-to solution in the on-board scale market.

Call For a Quote:

(833) 934-4448

Maximize Loads AND Eliminate Overweight Fines

Over-load Protection

Exceeding the maximum legal allowable weight for a vehicle carries a range of risks to the driver and others, and can result in hefty penalties such as fines, shutdowns, seizure and loss of business. Knowing the total and axle weights while being loaded can prevent overages from happening, saving you time and providing protection from the costly alternatives before you begin driving.

Under-load Prevention

For the majority of commercial truckers, the more you haul each trip, the more money you earn. Every time your truck is under-loaded, you are leaving money behind. How much is this costing you in trip efficiency? Know your weight with confidence and unparalleled accuracy before you leave the loading site. This ensures you are maximizing your vehicle payload every time.

Quick and Simple Installation

While most other on-board scale systems can easily take 12 hours to install, Strong Weigh is incredibly quick and easy: No tedious and time-consuming running of wires along the frame and down the axles, which are bound to get damaged later. Simply install the wireless strain sensor on the front and rear axles, depending on the suspension type. Then install the small control box near the cab, and you’re done – most systems can be installed in less than 1 hour with minimal training.

Strong Weigh includes the only scale system with truly wireless sensors for every type of axle and suspension (including walking beam, leaf spring, and air ride), with replaceable batteries that can last up to three years. Plus the Strong Weigh control box boosts the wireless signal strength, so the driver can always view the truck’s weight, without needing to exit the cab.

NO

Running or Exposed Wires

NO

Bolting or Welding Required

Trip Transparency, Theft Prevention, ELD & More!

Accurate Real-Time Weight Data

Strong Weigh wirelessly transmits accurate scale data to the driver via a smart device or dedicated display, giving them peace of mind the truck is being used to its fullest potential without being overloaded. Additionally, you can log your trucks weight according to the DMV record-keeping requirements, with just the press of a button.

Fleet Management Capability

By adding Strong Weigh’s real time scale data to the power of telematics, you have a command center view of every truck and trailer in your fleet. Knowing where and what they weigh at any given time allows you to see and be notified instantly of pick-up and delivery or even unscheduled weight changes during a trip.

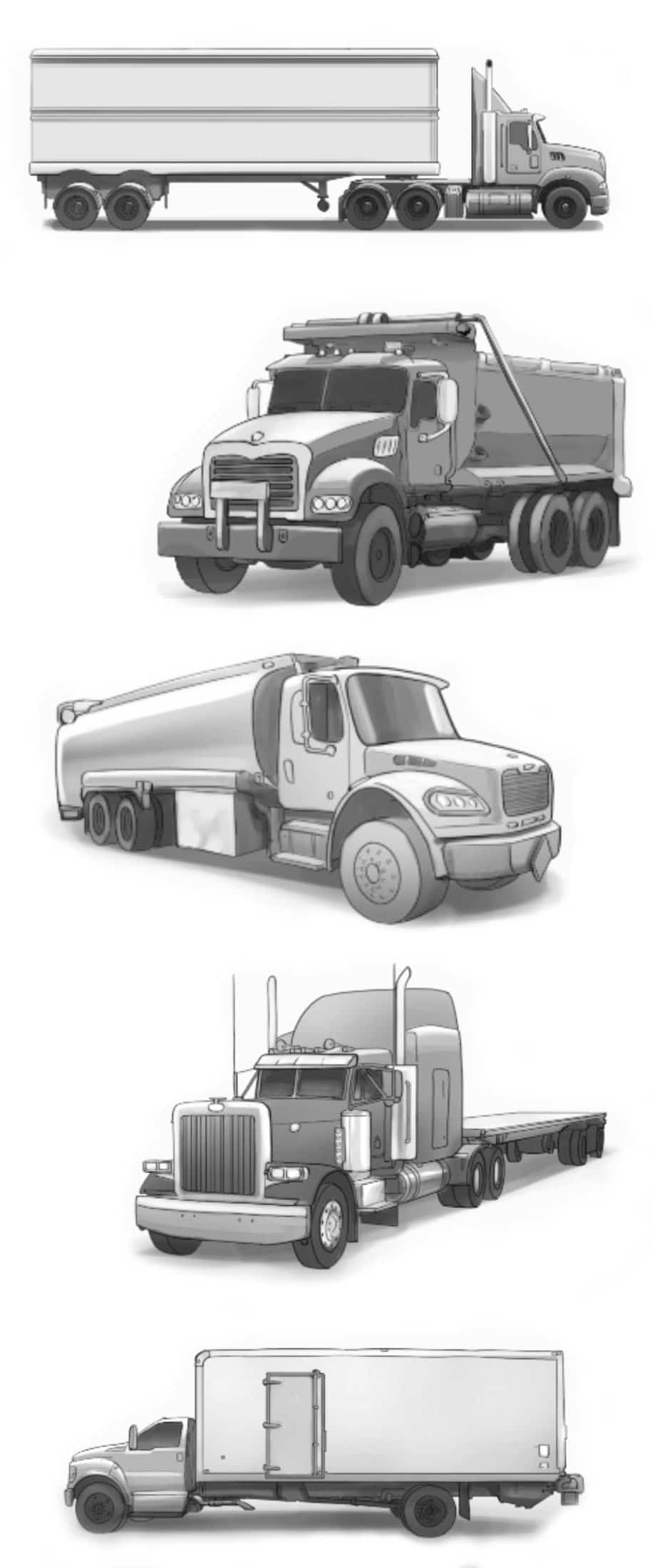

Flexible and Modular For All Truck Types

The components of Strong Weigh can be linked together in many different ways. A different suspension type merely needs a different configuration of Strong Weigh parts. The most common suspension types can be found here, but even uncommon or unique suspension types can be dealt with by contacting us and explaining your vehicle.

Straight Truck

The typical straight truck requires modular sensors for maximum accuracy. It is this configuration which has allowed us to reach a less than 0.1% margin of error. The sensors are coupled with the Strong Weigh Host Controller, which is installed in the truck frame near the cab of the truck, and connect to the truck’s diagnostic port.

Straight Truck w/ Air Suspension

Air ride suspensions use the Strong Weigh Wireless Pressure Transducer, which easily tees into the air line that supplies the suspension’s air bags. For typical air ride suspensions, all of the air bags share a common air supply line, and thus require only one Wireless Pressure Transducer. However, some air ride trucks are configured with each axle having it’s own air supply, usually so that one axle can be lifted when not needed, and in this case one Wireless Pressure Transducer is required for each axle. Additionally, the Strong Weigh Modular Sensor is needed for improved accuracy. The sensors are coupled with the Strong Weigh Host Controller, which is installed in the truck frame near the cab of the truck, and connect to the truck’s diagnostic port.

Walking Beam Suspension

Walking beam suspensions, like the Hendickson Haulmax suspension for example, use multiple Wireless Modular Sensors installed on the walking beams – both on the driver and passenger sides. The sensors are coupled with the Strong Weigh Host Controller, which is installed in the truck frame near the cab of the truck, and connect to the truck’s diagnostic port.

Leaf Spring Suspensions

Leaf spring suspensions on drive axles will typically have Wireless Modular Sensors installed on the trunion tube. Additionally, a Strong Weigh Modular Sensor is needed on the front steer axle. The sensors are coupled with the Strong Weigh Host Controller, which is installed in the truck frame near the cab of the truck, and connect to the truck’s diagnostic port.

Tractor Trailer

The Strong Weigh On-board System works on virtually any type of tractor-trailer setup. Configuration of the Modular Sensor and/or Pressure Transducer combination are dependent on the suspension type of both the truck and trailer. Additionally, a Strong Weigh Modular Sensor is needed on the front steer axle. The sensors are coupled with the Strong Weigh Host Controller, which is installed in the truck frame near the cab of the truck, and connect to the truck’s diagnostic port.

Uncommon Truck Designs